Mechanical Design Analysis

A Mechanical engineering design analysis service is a specialized professional service that helps companies evaluate, optimize, and validate the design of mechanical components, assemblies, or systems before they are manufactured or placed into service. It combines engineering principles, advanced simulation tools, and practical industry experience to ensure that a product will perform as intended under real-world operating conditions. This type of service is widely used in industries such as automotive, aerospace, consumer products, heavy equipment, and industrial machinery to reduce development risks, lower costs, and accelerate time to market.

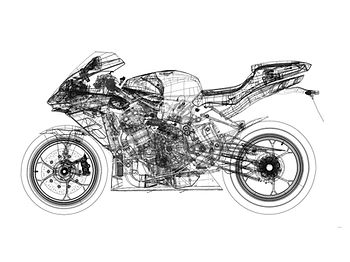

At its core, mechanical engineering design analysis involves studying the behavior and performance of a design concept to verify its structural integrity, durability, functionality, and safety. Engineers begin by reviewing the product’s design requirements, constraints, and operating environment, such as loads, stresses, temperatures, motion, vibration, and fatigue conditions. They then create or use existing three-dimensional computer-aided design (CAD) models to represent the components and assemblies being evaluated. These models serve as the foundation for further computational analyses and simulations.

Forensic Engineering Services

Veritech’s Real-World Expertise in Mechanical Design Analysis

Veritech Consulting Engineers combines advanced education, hands-on industry experience, and cutting-edge software tools to deliver comprehensive CAD modeling, Finite Element Analysis (FEA), and design functionality analysis services. Our team includes mechanical engineers with strong backgrounds in materials science, structural mechanics, dynamics, thermodynamics, heat transfer and fluid dynamics, enabling precise interpretation of complex simulations.

Our engineers are proficient in 3D CAD modeling, creating detailed digital assemblies that serve as the foundation for FEA and design analysis. This ensures that designs account for manufacturing constraints, tolerances, and assembly considerations, bridging the gap between virtual models and physical components.

Beyond simulations, mechanical design analysis often involves design optimization—an iterative process that adjusts geometry, materials, or configurations to:

-

Improve strength-to-weight ratios

-

Reduce manufacturing costs

-

Enhance performance

-

Enhance durability

Engineers also conduct tolerance analysis and manufacturability assessments to ensure designs can be efficiently fabricated and will function properly despite normal production variations.

Reporting and Recommendations

After analysis, engineers provide technical reports, design recommendations, and risk assessments. These deliverables:

-

Identify weaknesses or potential failure points

-

Highlight safety concerns or performance issues

-

Support regulatory compliance and industry standards

By addressing design problems early, companies can avoid costly redesigns, field failures, and warranty issues, ensuring products are safe, functional, and ready for market.

Finite Element Analysis (FEA) for Stress and Performance

Stress concentrations are critical considerations in mechanical design, as localized areas of high stress can lead to component failure if not properly addressed. To identify and mitigate these risks, engineers rely on advanced tools such as Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD), and motion simulation to evaluate a product’s behavior under real-world conditions.

Finite Element Analysis (FEA) divides a part or assembly into small, discrete elements and uses numerical methods to predict how it will respond to forces, pressure, heat, or other environmental conditions.

FEA can identify:

-

Stress concentrations and critical load points

-

Component deflections under operational loads

-

Natural frequencies and potential vibration issues

-

Areas prone to failure or fatigue

Similarly, Computational Fluid Dynamics (CFD) is used to analyze fluid flow, heat transfer, and thermal behavior within or around a mechanical system. These simulations allow engineers to evaluate design alternatives virtually, reducing the need for costly prototypes and accelerating development timelines.

Veritech's engineers are well-versed in conducting FEA studies to evaluate:

-

Structural performance and durability

-

Stress and deflection under operational loads

-

Fatigue life and potential failure points

-

Vibration and thermal performance

Combined with design functionality analysis, our engineers study how mechanisms move, interact, and perform as integrated systems. By assessing kinematics, load paths, vibration, thermal behavior, and lifecycle performance, it is possible to ensure that products will operate reliably in real-world conditions.

Motion Kinematics and Fatigue Analysis

Mechanical design analysis also includes motion and kinematic studies to assess how components move, interact, and transfer forces. This is essential for systems with gears, linkages, bearings, or moving parts where alignment, clearances, and wear patterns are critical.

Additionally, fatigue and lifecycle analyses estimate a component’s lifespan under repeated loading, helping ensure it meets safety and reliability standards over its intended service life.

Rainflow Counting

Rainflow counting is an analytical method used in fatigue analysis to evaluate how materials and components respond to variable cyclic loading. Unlike constant-amplitude fatigue tests, real-world products and structures experience irregular, fluctuating stress patterns over their service lives. These variable stresses can lead to premature fatigue failures if not properly understood and accounted for in the design process.

The rainflow cycle counting method converts complex load-time histories into a simplified series of stress-reversal cycles, making it possible to accurately estimate cumulative fatigue damage. By classifying stress ranges and mean stresses into a clear fatigue histogram, engineers gain insights into the durability and structural integrity of critical components. This process is essential for applying fatigue life prediction models which help determine how long a part can withstand real-world service conditions before cracks or failures occur.

Whether you are seeking to understand why a component failed, extend the service life of existing equipment, or ensure reilability and compliance, rainflow counting for fatigue analysis is a vital tool. Veritech engineers have the experience and technical expertise to transform complex load histories into reliable predictions of product performance, helping you reduce risk, improve design, and avoid costly failures. By integrating rainflow counting into our fatigue investigations, we provide clients with clear, scientifically grounded assessments for use in litigation support.