Forensic Engineering

Veritech Consulting Engineering employs licensed professional forensic engineers for the investigation and analysis of mechanical failures and motor vehicle accidents. Veritech’s forensic engineers are experienced in product failure analysis and product liability investigation as well as reviewing complex engineering designs for the analysis and evaluation of patent infringement claims. Veritech engineers are selected for their unique and varied backgrounds which enable them to approach complicated problems from several different viewpoints to ensure thorough and accurate solutions. Our extensive experience in forensic engineering matters includes investigations ranging from motor vehicle accidents to unique incidents involving medical equipment failures, construction accidents and various manufacturing or design defects.

Forensic Engineering Services

Understanding Forensic Engineering

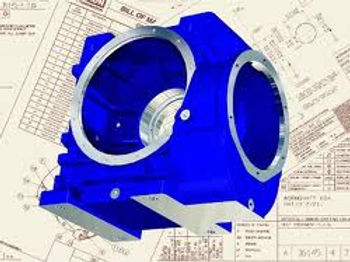

Forensic engineering is the application of engineering principles to investigate mechanical failures, accidents, and product malfunctions. Often referred to as reverse engineering, forensic engineers analyze evidence to determine the root cause of failures, which can include design flaws, manufacturing defects, improper maintenance, or operator misuse.

_JPG.jpg)

Forensic engineering is commonly utilized in cases involving:

-

Personal injury claims

-

Industrial accidents

-

Motor vehicle crashes

-

Product liability disputes

-

Large financial losses due to equipment or system failure

By understanding how and why a product or machine failed, forensic engineers provide valuable insight for litigation, insurance claims, and product improvement initiatives.

When is a Forensic Engineer Needed?

Forensic engineers are often called upon when a mechanical failure or accident occurs, especially when it results in personal injury or significant financial loss. Attorneys and insurance companies rely on forensic engineers to:

-

Examine and analyze evidence

-

Determine the root cause of a failure

-

Provide independent, unbiased expert opinions for potential use in litigation

In litigation, forensic engineers prepare detailed reports that may be submitted to courts and opposing parties. They also provide expert testimony in depositions, discovery, or trial settings, explaining complex engineering concepts in a manner that is understandable to judges and juries.

Common Sources of Product Failures

Based on Veritech’s experience investigating hundreds of product failures and motor vehicle accidents, common component and system failures fall into four categories:

_JPG.jpg)

_JPG.jpg)

1. Design Defects

Design defects are systemic issues present across multiple units of a product.

Examples include:

-

Incorrect material specifications

-

Improper part thickness

-

Inadequate clearance between components

-

Failure to account for assembly tolerances

The presence of other similar incidents (OSIs) often indicates a design flaw.

2. Manufacturing Defects

Manufacturing defects are typically isolated occurrences caused by improper processes or assembly. Investigating these failures may require collaboration among:

-

Materials science professionals

-

Manufacturing professionals

-

Mechanical engineers

3. Improper Maintenance

Failure to follow manufacturer-recommended maintenance schedules can lead to accidents. Examples include:

-

Worn brake pads or consumable parts

-

Neglected inspections of articulating joints or pivot points

-

Inadequate lubrication, service, and wearable part replacement

4. Product Misuse

Operator misuse can result from inadequate training, intentional misuse, or failure to follow safety instructions. Misuse increases the risk of injury or equipment failure.

Mitigation of Potential Hazards

Manufacturers use risk management tools to prevent failures and enhance safety. Common techniques include:

-

Failure Mode Effects Analysis (FMEA)

-

Developed in the 1940s by the U.S. military

-

Identifies potential failures in design, manufacturing, and assembly

-

Helps manufacturers proactively mitigate risks before products reach consumers

-

-

Design Hierarchy (Design-Guard-Warn - Prioritizes hazard mitigation strategies:

-

Design hazards out of the product

-

Guard against hazards when elimination is not possible

-

Provide clear warnings when hazards cannot be removed or guarded

-

-

ANSI Safety Label Standards (ANSI/NEMA Z535.4) - Requires warnings to include:

-

Identification of the hazard

-

Severity of the risk

-

Potential consequences

-

Steps to avoid the hazard

-

Why Choose Veritech Forensic Engineers

Veritech’s team offers comprehensive forensic engineering expertise, combining:

-

Hands-on industry experience in product design, development, and manufacturing

-

Proven track record in mechanical product failure investigations

-

Expertise in consumer products, industrial equipment, and medical devices

-

Court-qualified testimony at both state and federal levels

Our engineers provide accurate, reliable, and defensible analysis for product failures, accidents, and mechanical mishaps. By leveraging both practical engineering experience and scientific methodologies, Veritech helps clients understand failures, mitigate risks, and support legal or insurance proceedings.